Components of FWG

This article explains the different components of an evaporator-type freshwater generator plant along with their functions.

The Previous Module

Let us understand how to start and stop a FWG.

Line Diagram first!

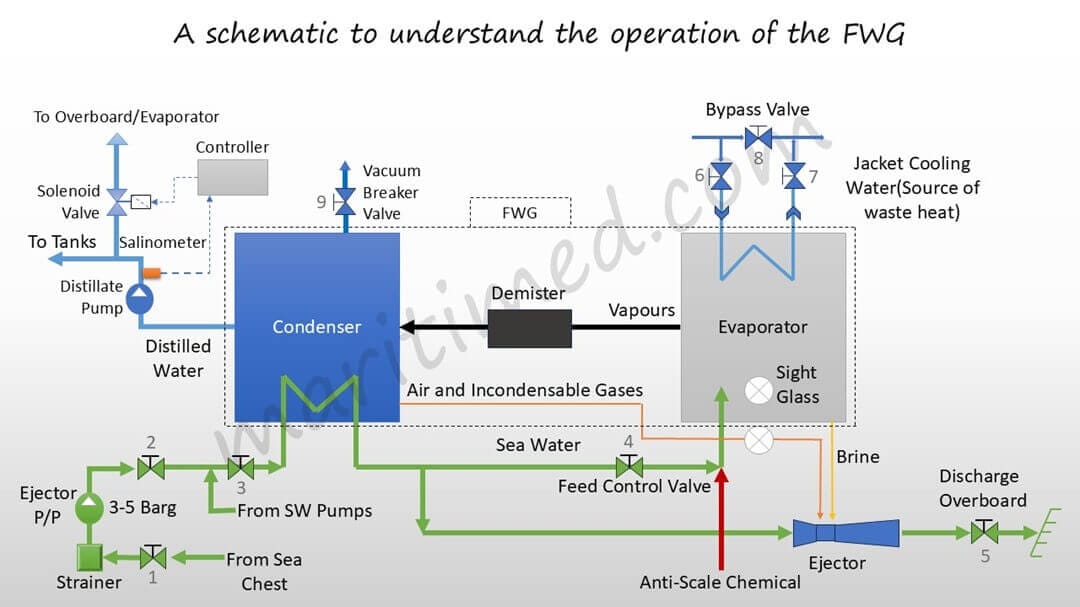

Before we proceed, let’s point out the valve numbers in the above diagram.

| Valve Number | Location |

|---|---|

| 1 | Ejector Pump Suction from the seachest |

| 2 | Ejector Pump discharge |

| 3 | SW inlet to FWG |

| 4 | Feed Control Valve |

| 5 | FWG Overboard Discharge Valve |

| 6 | JCW in |

| 7 | JCW out |

| 8 | JCW bypass valve |

| 9 | Vacuum breaker valve |

Starting the FWG plant:

- Open the valves 1, 2, 3, and 5 completely.

- Start the FWG Ejector Pump. Confirm the discharge pressure is in the range of 3-5 barg.

- Close the vacuum breaker valve 9. Usually, an 85-90% vacuum is maintained.

- Open the JCW valves 6 and 7, and slowly close the bypass valve 8 to gradually increase the shell temperature to 40-50 deg C.

- Use the feed control valve to adjust the feed rate such that the brine level on the evaporator sight glass is near the half mark.

- You might see bubbling through the sight glass at the surface of the brine.

- Wait until you see water in the sight glass fitted on the air ejector line.

- Start the distillate pump and observe the salinity on the controller.

- Once the salinity is less than the set point(usually 15 ppm), the solenoid valve will close, and the water will either go directly to the distillate tank or the FW tanks through a mineralizer/sterilizer.

- Dose the anti-scale chemical like Vaptreat in the Dosing Tank. Such chemicals are used to reduce the scaling in the FWG.

- Put the alarm switch on the controller to ON.

Stopping the FWG plant:

- Disable the alarm on the controller.

- Stop the distillate pump.

- Open the bypass valve 8 completely.

- Close the JCW valves 6 and 7.

- Allow the ejector pump to run for at least 30 minutes. This will cool down the FWG.

- Stop the ejector pump and close the valves- 1, 2, 3, and 5.

- Open the vacuum breaker valve.

💡

It is a good practice to open the vacuum breaker valve after stopping the FWG to prevent undue and unnecessary stresses on the gaskets.

FW to Tanks

The water produced by the FWG is not for consumption yet. It still lacks the minerals needed by the body. To do so, it is passed through a mineralizer, which adds minerals to the water, making it Fresh Water.

When filling the distillate tanks, the water can be directly passed to the tank without the mineralizer. Most ships have a distillate tank for storing distillate water for operational needs like Boiler Feed water, and sometimes cooling FW water.